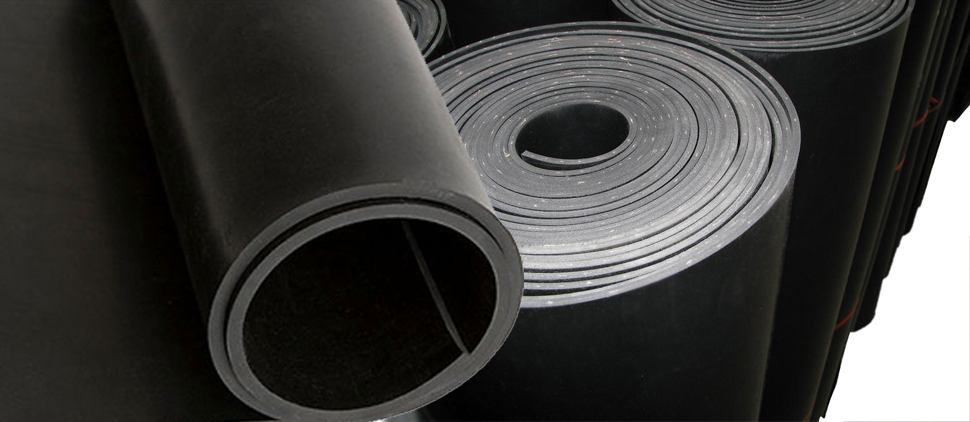

Neoprene Traits and Applications

Neoprene rubber is a synthetic rubber composed of polymerized chloroprene, and is from time to time referred to as polychloroprene. Polychloroprene is mainly composed of carbon, hydrogen, and chlorine polymers, which are cross-linked to give neoprene certain desirable properties, such as chemical inertness, and thermal, oil, water, and solvent resistance. When cross-linking occurs during vulcanization, sulfur bridges are formed that join individual chains of chloroprene to produce a bigger molecule. The figure of sulfur links affects the largely neoprene properties. consequently, depending on how chloroprene is vulcanized and how many sulfur bonds are formed,.

Neoprene rubber is an all function elastomer and an exceedingly versatile synthetic rubber used in thousands plus applications. Neoprene rubber resists degradation from sun, ozone and weather and performs well in contact with oils and chemicals. This type of rubber maintains its strength, flexing, twisting and elongation awfully well above a large temperature range while having stupendous physical toughness. Many grades of neoprene are available depending on the application.