August 7 Latest Updates admin Comments Off on Eid Holidays

This is the announcement to inform you that Eid holidays will start from the 27-03-2025 to 01-04-2025.

The first working day will be 02-04-2025 office timing : 8:30-AM to 05:30 PMin case of any emergency inquiry during the holidays you may contact to direct number: 0301-8415249

Please only in emergency cases you may contact.

Best & Thanks Regards,

Leading Technologies

August 7 Latest Updates admin Comments Off on Happy Eid Mubarakh

Dear All’z

Wish you a great smile, laugh and successes for you on this day of Eid. Have a wonderful Eid day. Eid Mubarak

Best Wishes for all of you.

June 10 Latest Updates admin Comments Off on Changing of address

In order to provide you a better level of service, we are moving our Sales Office to a new premises with effect from Feb 2024. Our new address will be as follows:

Leading Technologies

Plaza No. 338 – First Floor, Commercial Area, Defence Main Boulevard. Phase 6, Lahore, Punjab. Pakistan.

Ph: +92 – 42 – 37180026 , Ph: +92 – 42 – 37180062 ,

From now all the deals will be from the new address & the mails will receive & send from this address.

For all future contacts and correspondence above may please be noted in your record. Contact Us

We thank you for your kind support and look forward to welcoming you at our new premises.

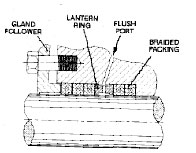

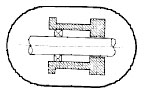

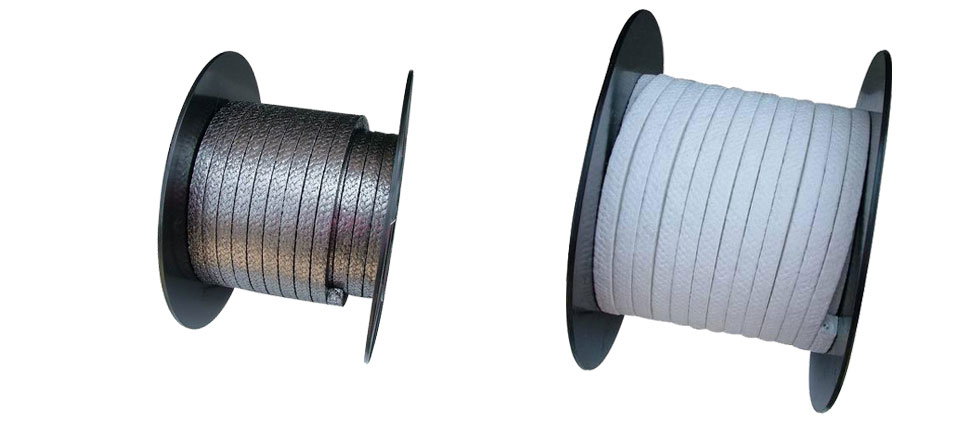

May 22 Latest Updates admin Comments Off on Installation Instructions for Pump Packing

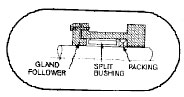

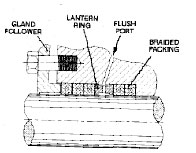

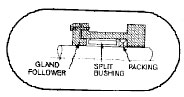

First Step:- By using packing hooks remove all the old packing, carefully remove the gland packing not to  damage the shaft/sleeve. It means all rings, even the ring below lantern ring and the lantern. After examining shaft/sleeve clean the stuffing box. If scored or deeply grooved, change worn parts.

damage the shaft/sleeve. It means all rings, even the ring below lantern ring and the lantern. After examining shaft/sleeve clean the stuffing box. If scored or deeply grooved, change worn parts.

Second Step:- Note the shaft diameter measurement, stuffing box depth and stuffing box bore. To conclude the accurate packing size, measure the diameter of the  shaft and the stuffing box bore. Subtract the shaft diameter from the bore diameter and divide the difference by two. This is the required cross-sectional size.

shaft and the stuffing box bore. Subtract the shaft diameter from the bore diameter and divide the difference by two. This is the required cross-sectional size.

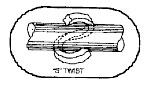

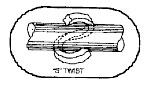

Third Step:- Always try to cut the packing into individual rings. Furthermore never wind the  gland packing into a coil in the stuffing box. Rings should be cut by using butt joint. Cut rings with a mandrel & the same diameter as the shaft in the stuffing box area. If there is no wear, rings can be cut on the shaft outside the stuffing box.

gland packing into a coil in the stuffing box. Rings should be cut by using butt joint. Cut rings with a mandrel & the same diameter as the shaft in the stuffing box area. If there is no wear, rings can be cut on the shaft outside the stuffing box.

Fourth Step:- Tightly hold the gland packing on the mandrel, remember do not stretch extremely. Cut the ring  and insert it into the stuffing box, making certain that it fits the packing space properly. Each additional ring can be cut in the same manner.

and insert it into the stuffing box, making certain that it fits the packing space properly. Each additional ring can be cut in the same manner.

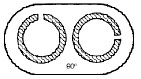

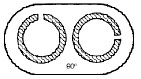

Fifth Step:- Install one ring at a time. Make sure it is clean, and take care while handling  don’t picked up any dirt . Lubricate the inner dia of each ring lightly. Stare one end & then the other, butted closely. Work around circumference from either or both directions. Joints of successive rings should be staggered and kept at least 90° apart. Each individual ring must be firmly seated with a tamping tool. When mostly rings have been individually seated than that the nose of the gland follower will attain them, individual tamping must be supplemented by the gland.

don’t picked up any dirt . Lubricate the inner dia of each ring lightly. Stare one end & then the other, butted closely. Work around circumference from either or both directions. Joints of successive rings should be staggered and kept at least 90° apart. Each individual ring must be firmly seated with a tamping tool. When mostly rings have been individually seated than that the nose of the gland follower will attain them, individual tamping must be supplemented by the gland.

Six Step:-If a lantern ring is provided, make sure the lantern ring is installed under the pipe tap hole.

Seven Step:- After the last ring is installed, bring the follower down on the packing and finger-tighten the gland nuts. Do not jam the packing by excessive gland loading. Start pump, and tighten the bolts until leakage is decreased to a tolerable minimum. Make sure gland bolts are tightened evenly. Stopping leakage entirely at this point will cause the packing to burn up.

Eight Step:- Allow packing to leak freely upon startup after repack. Gradually reducing leakage during the first hour of operation will result in a better seal over a longer

damage the shaft/sleeve. It means all rings, even the ring below lantern ring and the lantern. After examining shaft/sleeve clean the stuffing box. If scored or deeply grooved, change worn parts.

damage the shaft/sleeve. It means all rings, even the ring below lantern ring and the lantern. After examining shaft/sleeve clean the stuffing box. If scored or deeply grooved, change worn parts. shaft and the stuffing box bore. Subtract the shaft diameter from the bore diameter and divide the difference by two. This is the required cross-sectional size.

shaft and the stuffing box bore. Subtract the shaft diameter from the bore diameter and divide the difference by two. This is the required cross-sectional size. gland packing into a coil in the stuffing box. Rings should be cut by using butt joint. Cut rings with a mandrel & the same diameter as the shaft in the stuffing box area. If there is no wear, rings can be cut on the shaft outside the stuffing box.

gland packing into a coil in the stuffing box. Rings should be cut by using butt joint. Cut rings with a mandrel & the same diameter as the shaft in the stuffing box area. If there is no wear, rings can be cut on the shaft outside the stuffing box. and insert it into the stuffing box, making certain that it fits the packing space properly. Each additional ring can be cut in the same manner.

and insert it into the stuffing box, making certain that it fits the packing space properly. Each additional ring can be cut in the same manner. don’t picked up any dirt . Lubricate the inner dia of each ring lightly. Stare one end & then the other, butted closely. Work around circumference from either or both directions. Joints of successive rings should be staggered and kept at least 90° apart. Each individual ring must be firmly seated with a tamping tool. When mostly rings have been individually seated than that the nose of the gland follower will attain them, individual tamping must be supplemented by the gland.

don’t picked up any dirt . Lubricate the inner dia of each ring lightly. Stare one end & then the other, butted closely. Work around circumference from either or both directions. Joints of successive rings should be staggered and kept at least 90° apart. Each individual ring must be firmly seated with a tamping tool. When mostly rings have been individually seated than that the nose of the gland follower will attain them, individual tamping must be supplemented by the gland.