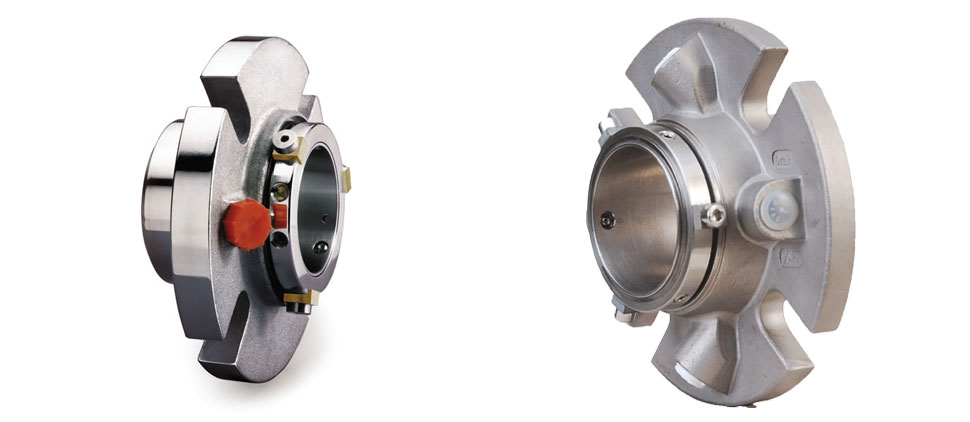

Rotary Seal

Rotary seals that provide hydrodynamic lubrication to minimize seal and shaft wear, and to accommodate high differential pressure. Rotary Seals are used for lubricant preservation and contaminant exclusion. Rotary Seal were formerly developed for the harsh & unforgiving oilfield down hole drilling surroundings, and provide an effectual solution to the stern service conditions found in a lot of special industries.

There are different types of Rotary Seal Available,

Labyrinth Seals

A labyrinth is distinct as a complicated network of passage. A labyrinth is provided to prevent the easy passage from the entry to the end / Exit.

This seal provide the similar function. The Labyrinth Seal restricts the passage of solid, liquid and gaseous contaminants into the sealed area and also restricts the leakage of fluid out of the sealed containment.

Non contacting rotary and stationary elements provide a restricted flow path & utilize centrifugal force and gravity to stop leakage.

Dissimilar other rotating e.g lip seals, the Labyrinth Seal will not scratch shafts & has a virtually limitless life, is frictionless, is largely unaltered by high or low temperatures & can be used for high shaft rotating speeds.

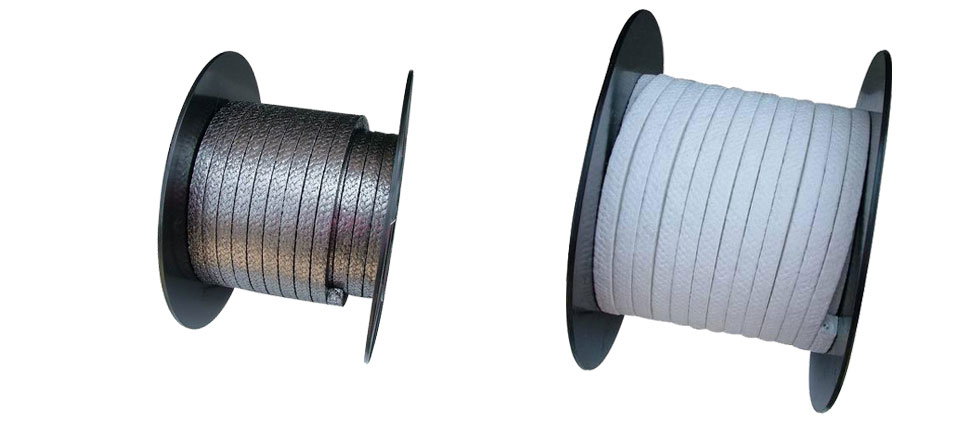

Felt Seals

Felt seals are mostly used as oil or grease seals for retaining lubrication & at the similar time preventing dirt entering into the bearing.

Felt seal has long been used for sealing duties because of many favorable properties such as wicking & oil fascination properties, very well filtering & resilience. This allows the felt to maintain a constant sealing pressure & as the seal wears the felt surface remains unaffected.

Felt seals are generally pre-saturated with lubricants of a superior viscosity than the bearings presenting positive bearing guard. If the seal does run dried out it will tend to shelter & polish the shaft slightly than cause damage. Through normal operating temperatures & conditions the felt seal is highly economical, normally requiring replacement when the machine is overhauled.

Ferro fluid Seals

Ferrofluid seals are much specialized rotary seal type which has advanced theoretical benefits.

Ferrofluid seal is a fluid ring which is retained in place among the rotating & fixed members under the action of magnetic forces.

Ferrofluidic sealing technology takes advantage of the reaction of a fluid, containing a uniform distribution of magnetic particles, to an applied magnetic field. It use a magnet with magnetically permeable north & south pole pieces & a magnetically permeable shaft to create a permanent magnetic circuit. The magnetic flux is concentrated in the gap under each pole and when ferrofluid is applied to this gap it assume the shape of a liquid o-ring and produces a hermetic seal.